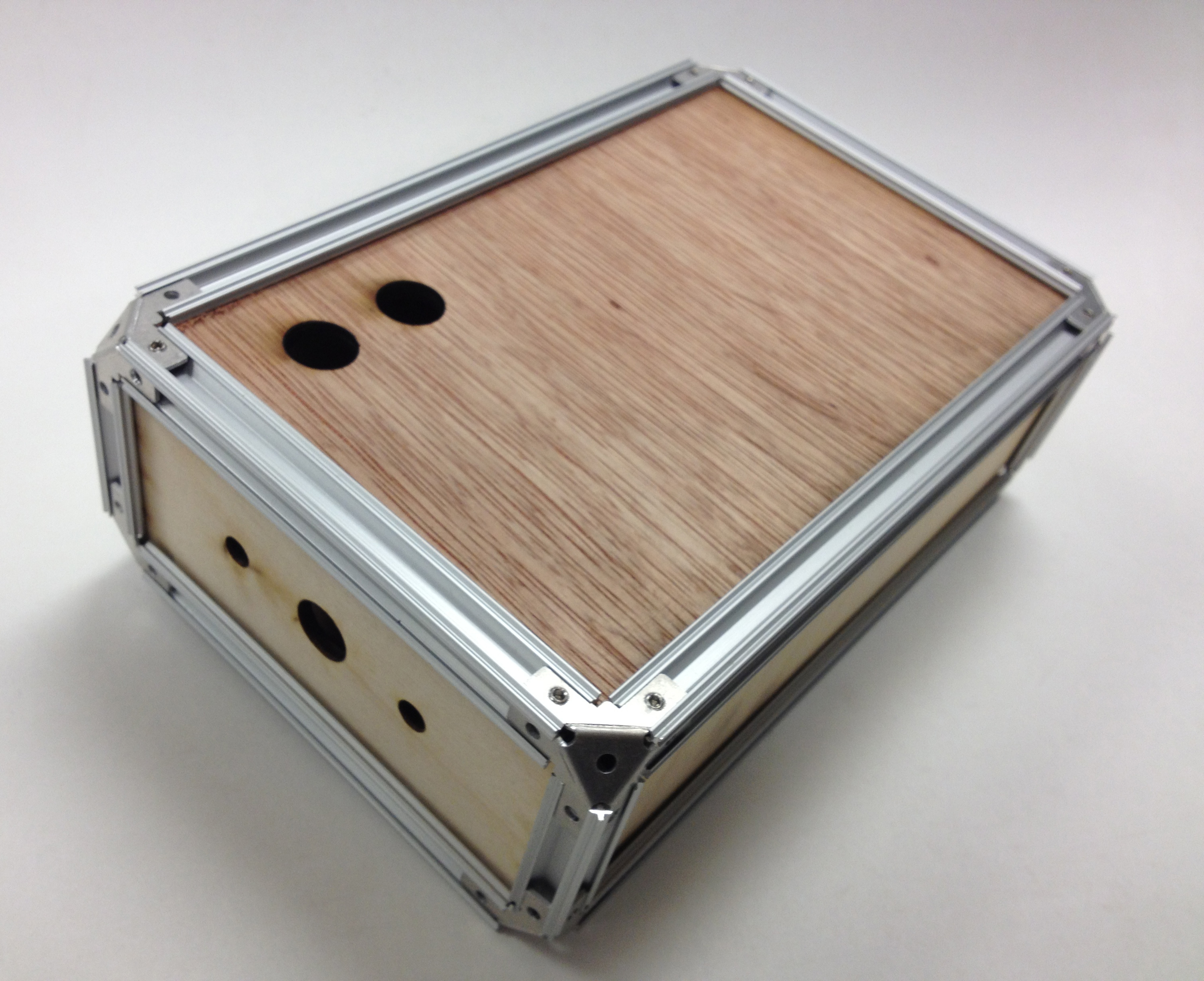

80 20 Aluminum T Slot Framing

80/20 is a T-slot aluminum framing system you can use to create virtually anything. One of the many benefits you’ll experience with 80/20 aluminum extrusions and parts is its versatility. The open T-slot concept allows exact positioning and repositioning, enabling you to make adjustments and modifications fast and precisely. An online deflection calculator for 80/20 is here. Using 1/10” or under as a target, what is the proper bar type to use at the length identified in Step 2. F&L Industrial Solutions offers free design and quotation of high quality 80/20 t-slot aluminum extrusion framing – so don’t be afraid to contact us to help. 80/20, known as 'The Industrial Erector Set'©, is a modular T -slotted aluminum framing system offered in both inch and metric profiles. It offers extremely cost-efficient solutions to building machine frames, guards, work stations, retrofit projects and more. Basically anything. And we do it all right here at Fiero Fluid Power! 80/20 provides T-slot aluminum profiles, or bars, that have channels used to connect other bars and parts — for instance, panels, linear bearings or casters. It is a building system anyone can use to create custom solutions. 80/20 UNIVERSITY One of the many benefits you'll find with 80/20 profiles and parts is its versatility.

While having everything cut for you ahead of time is the recommended way to go, sometimes you just don’t know the length of every bar until you start building your frame. Or you just want to save some money (i.e. the cut charge).

In these cases, you are going to need to know how to cut an aluminum bar yourself. Two of the biggest advantages of aluminum over steel is its weight-to-strength ratio and the ability to cut it yourself with a standard saw.

What You Need To Know When Cutting 80/20 Aluminum T-Slot Extrusions

These common Questions & Answers about cutting aluminum extrusions should help you get started:

Question 1: Can I use my circular or table saw?

Answer: Yes, but we recommend that you use the right blade and take some measures to ensure the squareness of the cut. Aluminum t-slot bars cut at the factory use expensive, calibrated saws to maintain exact squareness.

When you use a table saw (which is preferable to the circular saw) to cut, there are a few angle errors that can occur. As table saw blades are fixed – all you need to do is make sure the blade angle is exactly 90 degrees and that the bar is square and secure before cutting. This usually involves confirming the angle of the blade, and holding the bar against the guide.

For circular saws, cutting 80/20 aluminum t-slot extrusions is a little more tricky. First make sure the base plate is parallel to your blade if you are going to use it to line up the cut. Like a table saw, also make sure the angle is set exactly to 90 degrees. Now, the tricky part is getting the blade through the aluminum without tilting the saw left or right. It might be worthwhile to set up some type of jig to ensure your Saw cannot rock back and forth as you move down, so the cut is square.

Question 2: What is the best blade to use for cutting 80/20 aluminum t-slot extrusions?

Answer: The best type of blade is a high-speed .375” steel blade with 60 – 72 teeth and carbide tips. Make sure the blade is a double or preferably a triple chip – this basically alternates a flat “rager” tooth with a higher “trapeze” tooth that divides the chips when cutting harder materials like Aluminum – also called non-ferrous. Cutting 80/20 aluminum t-slot extrusions is relatively easy as they are composed of aluminum alloy 6105-T5 – which is specifically formulated for machining.

Question 3: Should I lubricate the blade while cutting?

Answer: Yes, you should definitely lubricant the blade with vegetable oil or a commercial lubricant like WD-40 or Trim Sol. If you don’t use lubricant, the blade will heat up quickly and the chips will re-weld themselves to the teeth of your blade. Avoid this!

Question 4: What RPM should I use?

Answer: If you can change the RPM of your saw, then you should use a slower speed. The saw’s RPM has to be matched with how fast you are pushing the blade through the aluminum and how thick the bar is. The faster you want to cut, the faster the RPM needs to be. If you move the blade too fast through the material, the blade will heat up and generate a lower quality cut. In general, you will have to go slower than what you are used to for wood.

Question 5: Any other recommendations?

Answer: Yes – definitely. Cutting 80/20 aluminum t-slot extrusions can be dangerous, so here are 5 safety precautions you should take:

- Use eye protection as cutting 80/20 aluminum t-slot extrusions generates a fair amount of hot flying metal chips. A face shield is better.

- Cutting aluminum can be loud so hearing protection is also highly recommended.

- Respiratory protection is recommended as dust created by aluminum cutting is toxic. Lubrication reduces this substantially and not everyone uses respiratory protection, but we recommend it.

- Make sure your bar is well secured. We highly recommend clamping it down securely before cutting. But if you don’t make sure it is held very securely. A loose bar of aluminum is one of the most dangerous things in the shop.

- Plan on deburring the end of the bar with a polishing wheel, metal file or metal sand paper. Even with a quality cut, the edges will be sharp and there may be small chips that will easily cut a hand or finger.

Summary

Cutting 80/20 aluminum t-slot extrusions is fairly simple with common saws if you follow the recommendations above. Why use or cut aluminum extrusions? Click here for 5 great reasons.

Having us cut your extrusions is far safer and likely more accurate. But just in case, we hope you have enjoyed this article. Want to make sure you get future articles – register now. Have questions? Give us a call at 1-858-602-1500 – we will be happy to help you.

This document covers a simple method to decide what size and shape of 80/20 t-slot bar is required for a particular project – based on the weight the structure must support. There are infinite ways of engineering a t-slot aluminum structure, but the method outlined below is simple and straightforward – and should be easy to understand by non-engineers. Although we reference 80/20 brand t-slot extrusion data in this article, you could draw usable conclusions for other t-slot aluminum profiles if their size, weight and shapes were similar to 80/20 Inc. t-slot products.

The basic principle of choosing the right bar is understanding when a bar starts bending (commonly referred to as deflection) under a specific weight load.

There are 9 common methods for calculating deflection for t-slot aluminum bars as outlined below:

Today, we will be looking at the Two-End Supported method using Load Centered weight (circled in the chart above). While the two-end fixed test method is closest to the common vertical corner post method of design, it assumes an unbreakable connection with the vertical post. As fastener strength will play a role in any fixed design strength, we will use the two end supported method to better illustrate independent bar strength. In general, bars will bend easier when supported on each end versus being actually fastened between two vertical posts; consequently, the data and conclusions provided here will have a magnitude of safety if used in a two end fixed configuration.

How strong is each extrusion type or bar? We get that question all the time. As outlined above, it all depends on what you do to the bar. But in our opinion, the cleanest, simplest way to judge bar strength and deflection is to look at how far a bar will bend if we put all the weight in the middle of the bar while supporting both ends.

At F&L Industrial Solutions, we use a target defection of 1/10” or under for most t-slot structures. If a bar has a chance of bending more than 1/10”, then we usually redesign with a stronger bar. So it is important to remember that target – a tenth of one inch or under.

Look at the chart below.

Maximum Weight Loads for 36″ Long 80/20 T-Slot Aluminum Bars

80 20 Aluminum T Slot Framing Screws

As you can see, the 80/20 t-slot called 1010 (which is a 1” x 1”) bar will bend 1/10” when 46 lbs. is applied to the center of a 36” long bar, while both ends are supported. If we were building a simple table, we might say that this table could hold a maximum of 184 lbs. (4 horizontal bars forming the table top) on the edges of the table (how much the center of a tabletop could hold would be dependent on the tabletop material and thickness – a good subject for another day). That same table designed with the 2020 series (2” x 2”) could hold up to 2,304 lbs on the edges.

Note: It is important to realize that some of the weaker fastening methods can only hold 200 – 400 lbs., so using a heavy-duty fastener is imperative to achieve the same strength as the bar. For example, there would be no reason to spend money on strong 2020 bars and match them with inexpensive and fairly weak corner brackets as the fasteners would break before the bar bent 1/10”. By using stronger connectors like end fasteners and anchor fasteners and external gussets, one can easily create connections that are as strong or stronger than the bar.

Click here to read about fastener strength in a past issue of Extrusion Builder News.

The graph above is a good starting point, but it is only one data point – for 36” long bars. A longer bar would bend at a much lower weight, and a shorter bar will bend a higher weight. Usually when we are designing a t-slot aluminum structure, we will add additional supports so that there is rarely long unsupported bars. For example, if a table top was 8’ feet long – we would normally put two additional cross braces under the table top, and at least 6 vertical legs – thereby eliminating any long bar from carrying too much of the load.

One last thing to think about when designing t-slot aluminum structures or frames with 80/20 or any other brand of aluminum extrusions is maximum load. While the cart or table or frame you are designing may only be used for holding a 50 lb. piece of equipment, what will happen if a large person stands on it and uses it as a way to change a high light bulb? When designing, you should design for the very worst case scenario that you want your frame to survive.

In summary, here are the 4 simple steps to determining the t-slot aluminum bar you need for your frame:

- What is the maximum load or weight that the structure will be exposed to?

- What is the longest bar length that will be used in your design?

- Find a deflection calculator for the t-slot aluminum bars you are using. An online deflection calculator for 80/20 is here.

- Using 1/10” or under as a target, what is the proper bar type to use at the length identified in Step 2.

80 20 Aluminum T Slot Framing Extrusions

Still confused? F&L Industrial Solutions offers free design and quotation of high quality 80/20 t-slot aluminum extrusion framing – so don’t be afraid to contact us to help. Click here to contact us to discuss your next project.

80 20 Aluminum T Slot Framing System

Ready to buy – visit our online Extrusion Shop.

Or call 858-602-1500.

80 20 Aluminum T Slot Framing Nailer

If you would like to download and use the 80/20 Inc. deflection calculator that we used for this article, just click here to download.